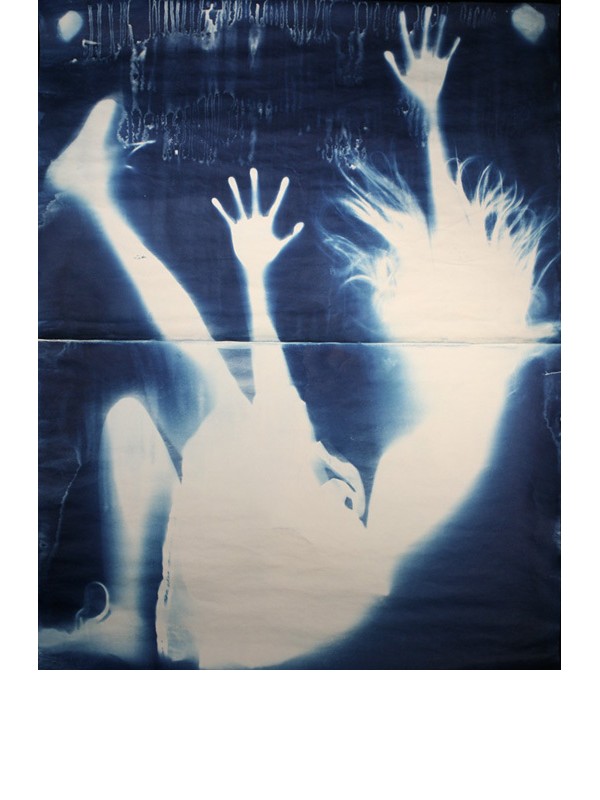

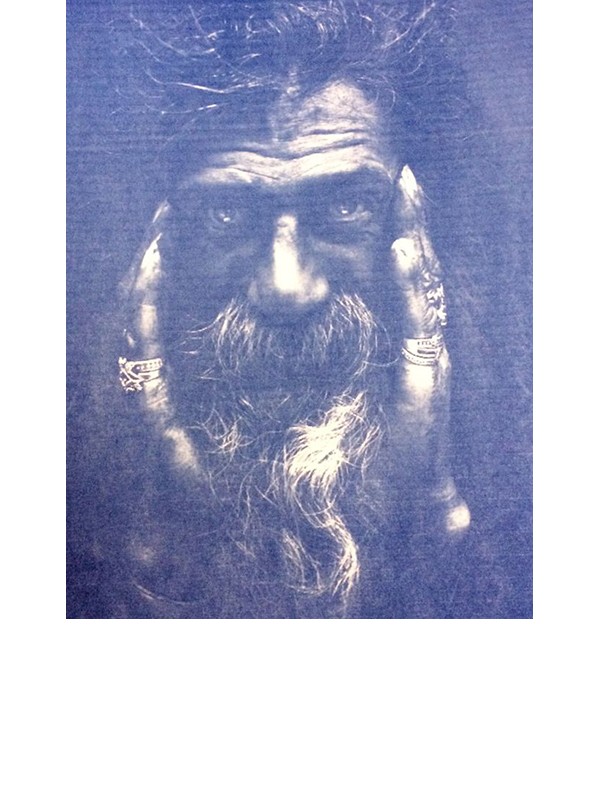

CYANOTYPE - BLUE PRINT A + B 250 ml + 250 ml

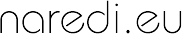

CYANOTYPE / BLUE PRINT

John Herschel, who is considered one of the leading scientists of his time, made significant contributions not only in mathematics and astronomy but also in various fields of science, including chemistry in photography. In 1842, he introduced his discovery – a photographic process he named cyanotype.

The use of cyanotype nearly faded away after the introduction of other photographic processes due to its characteristic blue color. Later, cyanotype was used until the end of photo secession – most often for making inexpensive contact copies from large-format negatives. The English used this process during the war in South Africa to produce banknotes and stamps. Until the invention of modern photocopying machines, the process was used to create copies of large-format plans.

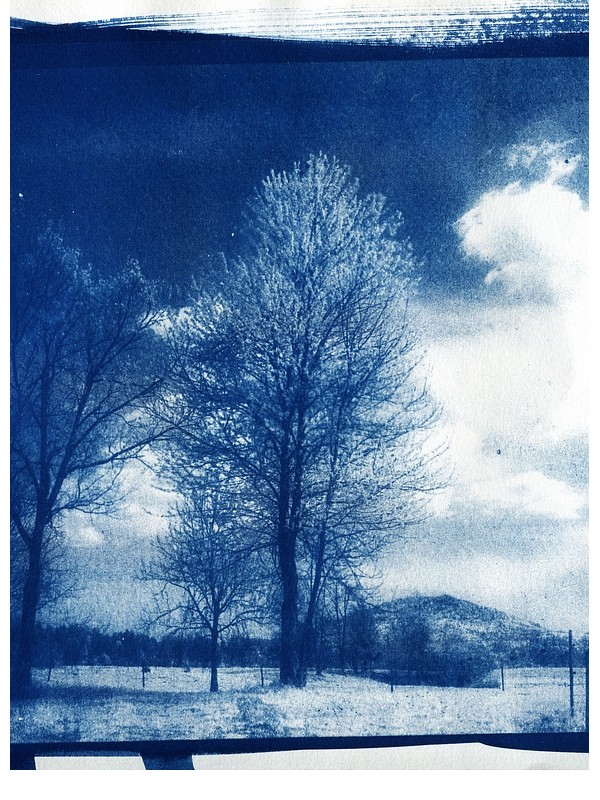

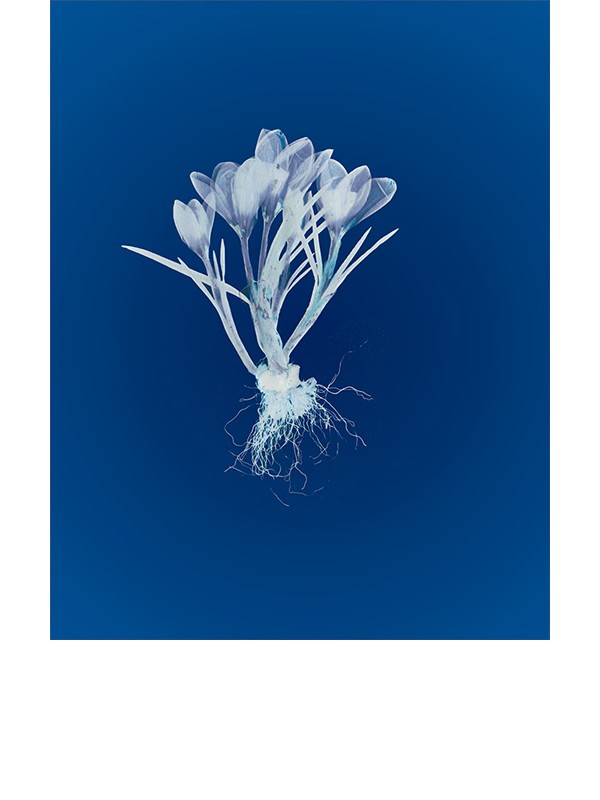

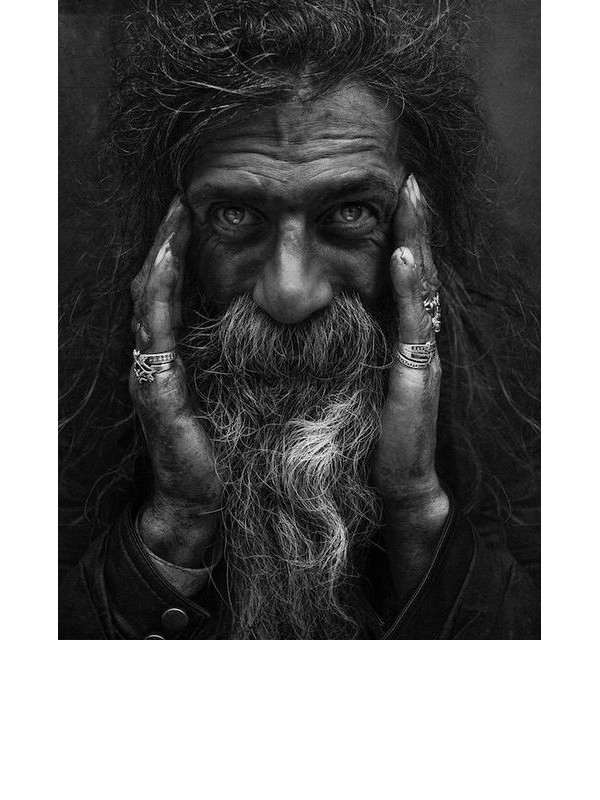

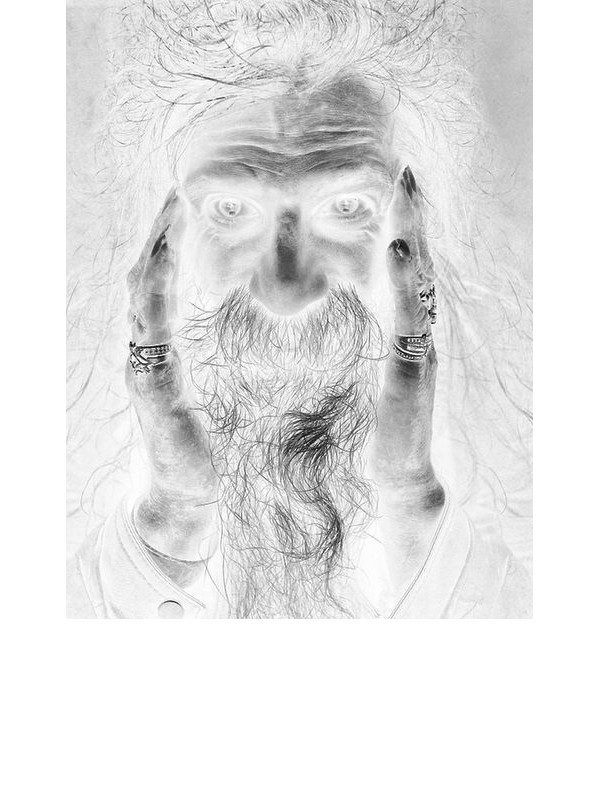

Today, this technique is experiencing a renaissance among enthusiasts of old techniques and classic materials, as it allows for unique artistic expression on various materials: paper, canvas, wood, textiles, ceramics,…

WORKING PROCESS

Perform steps 1 to 4 in a darkened space without direct sunlight or other UV sources.

1./ Mix components A and B in a volumetric ratio of 1:1 (a quantity of 4+4 ml=8 ml is sufficient for coating A4 format paper)

2./ Apply the solution with a soft, wide brush (without metal parts) onto the surface of paper, wood, fabric, or other absorbent

surfaces, which should have as neutral a pH as possible.

3./ Allow the surface to dry thoroughly

4./ Place and fix the negative printed on transparent film onto the surface (you can also use parts of plants, lace, or various other objects)

5/ LIGHTING - expose to sunlight or under a UV lamp. The required time greatly depends on the intensity of the UV source; under direct sunlight, for example, 5-15 minutes, in cloudy weather 30 minutes or more.

6/ FIXING - perform by rinsing in water. Rinse thoroughly for a few minutes. An intense blue color will appear during this process.

7/ To intensify the blue shades, you can coat the surface with INTENSIFYING AGENT and rinse again. It is recommended to use protective glasses and gloves while working.