SHELLAC

HISTORY and EXTRACTION

With the development of new overseas trade routes to the Far East, shellac appeared in Europe in the 17th century.

It is a resin of animal origin secreted by scale insects (Kerria Lacca, Collus Lacca, Tachardia Lacca Kerr, and several other Tachardia insects) that feed on the resin of various tree species such as Croton lacciferum, Euphorbiaceae, Ficus religiosa, Artocarpus, and some species of Butea, primarily in Eastern India, Sri Lanka, and the Antilles.

Raw shellac is collected on tree branches as a 3-8 mm thick crust, which contains numerous female scale insects. The locals collect it, crush it, and wash it with water. This removes wood fibers, sugars, water-soluble salts, and the red dye lac dye. Shellac is then heated, filtered through fabric, and the resulting melted mass is manually stretched into thin layers, similar to dough. Once cooled, it is manually or mechanically crushed into flakes of various sizes or ground into powder.

VARIETIES OF SHELLAC

Filtered and ground shellac contains up to 5% wax. Depending on the type of wood and its geographical location, shellac varies in color. The most characteristic representatives are:

- lemon (yellowish color)

- orange (orange-brown color)

- ruby (reddish-brown color)

For polishes with a particularly high gloss, the following are used:

- decolorized shellac without wax (almost colorless or slightly yellowish in thin layers)

- shellac gold

- shellac orange without wax

PREPARATION OF SHELLAC

To prepare the polish, shellac is dissolved in ethanol or a combination of alcohols (e.g., Shellac solvent – Samson Kamnik d.o.o.). For the highest quality polishes, various other natural resins are also added to the shellac solution, such as mastic (resin from Pistacia lentiscus from Chios-Greece), copal (fossil resin from Zaire or resin from living trees Trachylobium, Hymenaea courbaril from Zanzibar, Mozambique, Australia).

The usual concentration of shellac in the solvent is 12-20%. The solution is left to stand overnight, then filtered. This prepared polish can only be stored for a few months because the drying times of the polish are extended due to hydrolysis.

POLISHING

Making quality polish requires quite a bit of skill and experience.

The process can be summarized in the following stages:

A/ Priming - rubbing in diluted polish

B/ Filling pores

C/ Covering polish

D/ Smoothing: - polishing

- re-polishing

Before polishing, the surface is sanded with sandpaper 600 or 800 or steel wool 000. The most important tool for polishing is the pad. It is made from cotton or wool, wrapped in a linen cloth. For priming and filling pores, we use coarse linen cloth, while for covering polish and smoothing, we use finer cloth. The pads are stored in a well-sealed glass container.

Priming:

The pad is soaked in a strongly diluted polish, which is poured into a shallow container, and it is rubbed into the surface of the wood with longitudinal and transverse movements. Let it dry thoroughly overnight.

Filling pores:

We can use the pad we used for priming. Now we use undiluted polish, and under the pad, we apply or add ground pumice. Pumice is a volcanic rock with a microporous structure and is used as a mild abrasive.

The wood dust created during sanding, pumice powder, and dissolved shellac form a filling mixture that must be rubbed into the wood pores with the pad.

Be careful not to add too much pumice, as the pores will turn gray.

Dry for at least 1 hour.

Then sand the surface with fine sandpaper.

Covering polish:

We form a firm pad, soak it in undiluted polish, and with longitudinal and transverse applications, first with stronger pressure, then with lighter pressure. We change the pad 1 to 2 times. Be careful not to drag the pad over the still wet surface or tear the already formed polish film. We help ourselves with a few drops of polishing oil, which we use to moisten the polishing pad from the underside. If the underside of the pad starts to shine, it is a sign that the cloth is clogged. Such cloth must be washed with alcohol. With the last pad, we must polish until it is completely dry. This brings the residues of polishing oil to the surface. Dry for at least 2-3 hours.

Then lightly sand again with fine sandpaper 600-800 or pumice powder.

Smoothing-polishing:

We use a pad with a fine linen cloth in combination with shellac polish with a few drops of polishing oil. With the polishing pad, we make quick, circular movements.

Let it dry overnight. Then sand only the deficient or poorly treated areas with pumice powder.

Let it dry for 2-3 days if possible.

Smoothing-repolishing:

We prepare a fresh pad with the finest linen cloth. We use strongly diluted polish and a few drops of polishing oil and polish with gentle, circular movements. Finally, we only add alcohol to "extract" the last residues of polishing oil. During this process, we change the linen cloth several times so that the residues of oil do not obscure the surface again.

The polish is dry after at least 60 hours.

Although shellac polish is properly applied, the surface is relatively sensitive to water, heat, and solvents.

Nevertheless, shellac polish has a special aesthetic effect and still represents a high level of craftsmanship in the treatment of wooden surfaces.

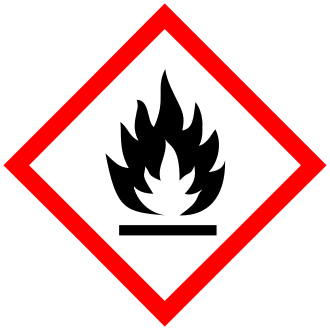

DANGEROUS

H225 Flammable liquid and vapour.

P101 If medical advice is needed, have product container or label at hand.

P102 Keep out of reach of children.

P103 Read the label before use.

P240 Ground the container and equipment for receiving the liquid and equalize potentials.

P241 Use [electrical equipment/ventilation equipment/lighting equipment/…] that is explosion-proof.

P280 Wear protective gloves/protective clothing/eye protection/face protection.

P303 + P361 + P353 IN CASE OF CONTACT WITH SKIN (or hair): Immediately remove all contaminated clothing. Rinse skin with water [or shower].

P501 Dispose of contents/container in accordance with regulations.