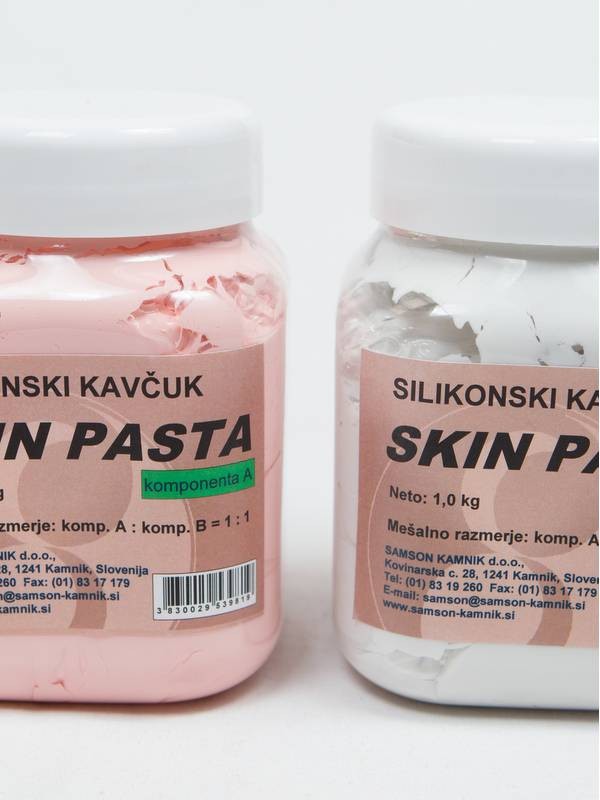

Skin safe Silicone rubber SKIN PASTE 1 kg + 1 kg

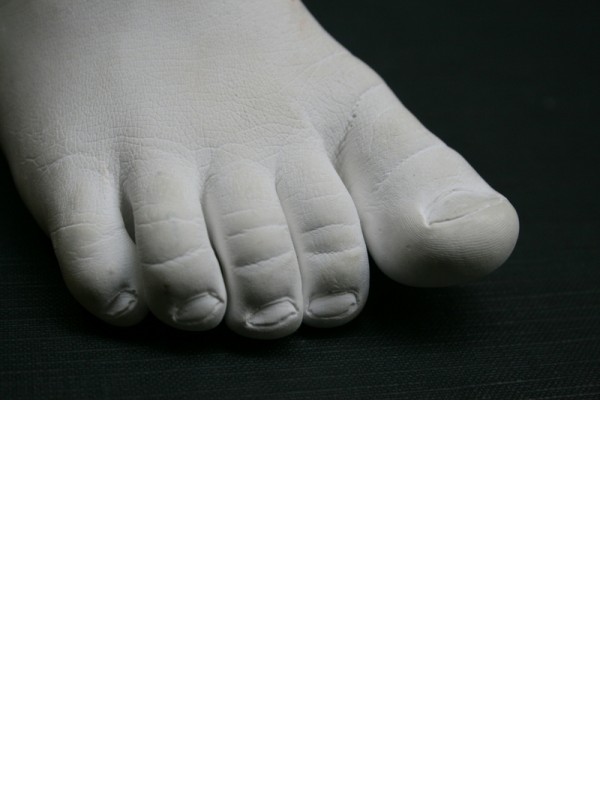

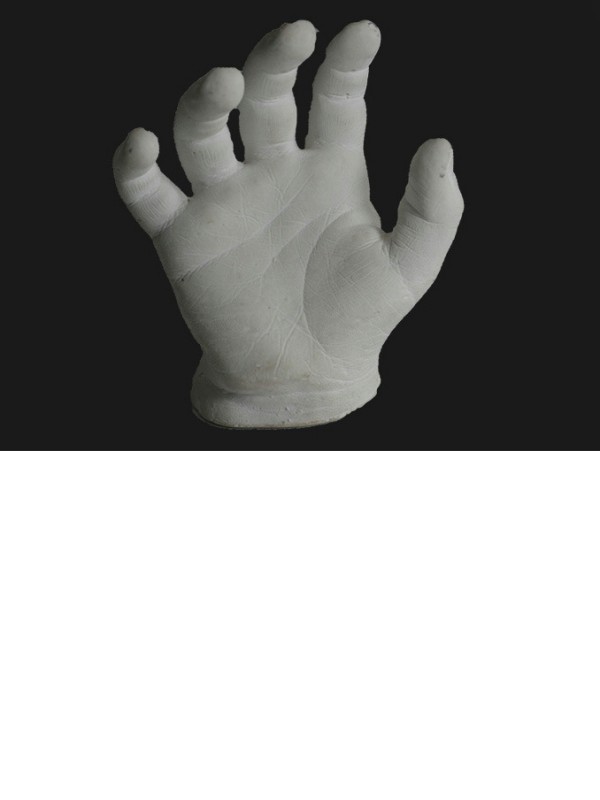

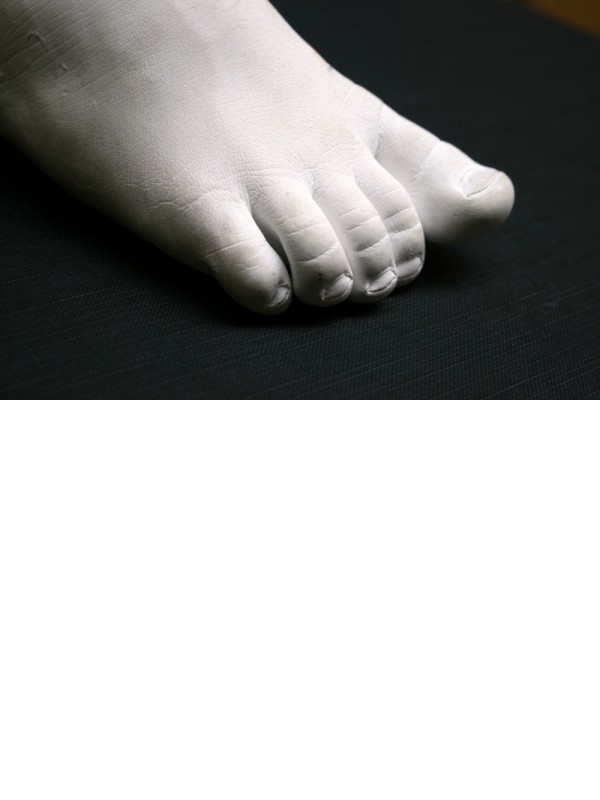

SKIN SILICONE is a very solid silicone rubber, used in lifecasting / body casting to create the shape of the face, hands or other parts of the body. The rubber quickly cures at room temperature and accurately conveys the shape of the body of any original model - better and faster than with any alginate.

Unlike alginate forms, suitable only for single use, flexible shell mold of SKIN SILICONE has been successfully used for multiple fills for the most complex and unusual products.

For casting the final products from the SKIN SILICONE made mold, you can use injection molding materials based on polyurethane (MODELIT SPEED and STANDARD) polyester and epoxy resins(EPOX 210),KREMENIT,gypsum, various types of concrete, the mixture for production of ceramics, and other similar materials.

The exact proportions 1 : 1 must be respected to obtain the correct pot life, curing time and to not alter the final characteristics of the product. The surfaces in contact with the silicone must be perfectly clean, free of grease and dry.

Usage

Weigh an equal amount of comp.A and comp.B (ex. 100 grams of catalyst and 100 grams of base; within a 5% error range the end result is not altered).

Use two different spoons for each component to prevent contamination of the product. Once the product is weighed and it is assured that the base and catalyst are equal, pour the components together and mix thoroughly. It is important to check while mixing that no residue remains on the base and sides of the container. Mix energetically until the colour of the product is homogeneous. Once the product is mixed it is applied to the mould or body. The pot life is approximately 2-3 minutes from the beginning of the mixing at 23°C. If the quantity used is less than what is needed to complete the duplication, complete the hardening of the silicone and than proceed with the addition of the remaining silicone needed. The material attaches to the silicone without altering the final result.