VIWOOD resin for making COLORED wooden-plastic composites 10 kg + 5 kg

VIWOOD

VIWOOD is a two-component low-viscosity casting compound suitable for filling cracks in wood and creating attractive wood and resin composites, making jewelry, furniture, tools, and more.

VIWOOD can be tinted with transparent liquid dyes KOLORO or opaque VIVAT pigments, wood flour, and mineral fillers.

Especially attractive effects can be created using EFFECT pigments

(Metallic,Neon, Pearl, Glitt, Sirius, Flip Flop)

PROPERTIES

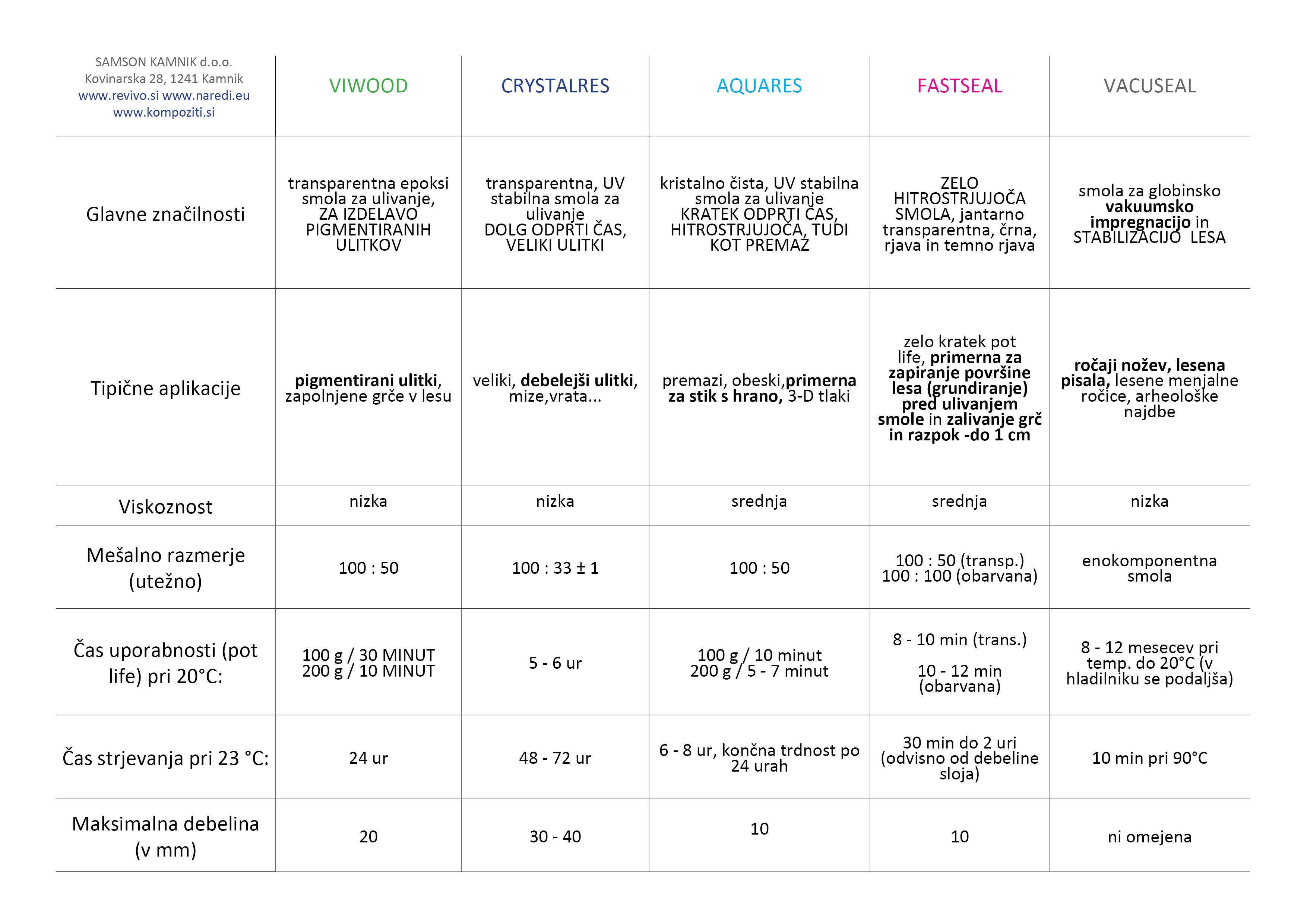

Mixing ratio: 100:50 (weight parts)

Time until the start of curing: 30 minutes (at 100 g)

Curing time: 24 hours at room temperature;

at elevated temperatures, the curing times are halved for every 10 degrees Celsius.

All our resins (except VACUSEAL) can be colored with:

1. KOLORO EPO pastes (excellent UV resistance, opaque or transparent color, easy mixing)

2. KOLORO liquid dyes (lower UV resistance, suitable for indoor use, excellent transparency)

3. VIVAT powdered pigments (excellent UV resistance, opaque or transparent color )

(VIVAT natural earths or VIVAT oxide pigments or VIVAT organic pigments)

4. EFFECT powdered pigments (pigments for special effects in resin)

FLIP FLOP pigments (different colors from different angles)

GLITT glitter (our series of glitters)

MAGNETIK pigments (magnetic pigments)

METALIK pigments (metal powder for a metallic look)

NEON fluorescent pigments (fluoresce in daylight, very vivid colors)

PERLA pigments (pigments with a pearlescent effect, endless color combination possibilities with VIVAT pigments and KOLORO liquid dyes)

SIRIUS luminescent pigments (absorb light during the day and glow at night)

UV-LUX pigments (pigments glow under UV light)

FLAKY (colored flakes)

General instructions for working with epoxy resins:

When working with casting compounds, it is very important to:

- weigh component A and component B

- use an accurate scale

- wear protective equipment (gloves,...) while working

- use mixing cups and sticks

- consider the open time and curing time of each compound

CASTING INSTRUCTIONS:

The resin is very liquid and self-leveling, so it needs to be contained or a mold needs to be made. It has very good adhesion to wood, stone, concrete,... so we use silicone molds or coat the surface of the mold made of other materials with a release agent.

We consider the recommended maximum thickness for each resin (the exact thickness depends on the type of resin, air temperature (higher temperature means we can pour thinner layers at once), humidity, shape of the product,...)

COLORING RESIN:

The amount of pigment/dye depends on the desired level of coloration and thickness of the product (for thicker layers, less pigment/dye is needed).

Coloring resin with VIVAT pigments or KOLORO EPO pastes:

For transparent colors, add 0.05 to 0.5% pigment by weight of the mass

For solid colors, add 2 - 5% pigment by weight of the mass

Always mix the pigment into component A, as this gives us enough time to mix the pigment (be careful not to count the weight of the pigment in the mixing ratio of components A and B).

MIXING INSTRUCTIONS:

Use the compound only at temperatures of 15 degrees Celsius and above.

Weigh the selected amount of component A into a mixing cup, add the correct amount of component B, and mix well (be careful not to incorporate too much air while mixing).

Pour the mixed compound into another cup, scrape the sides of the first cup, and mix well again. By mixing in two steps, we avoid curing issues due to poorly mixed mass. Gently tap the cup on the surface to release air bubbles (bubbles float to the surface).

The usability time of the compound (the time available for mixing and pouring) and the curing time depend on the type of compound and air temperature.

LATER PROCESSING:

Once the compound is fully cured, it can be sanded and polished. Sanding achieves a uniform height with the wood, while polishing restores the high gloss to the resin that it loses during sanding.

EXAMPLE:

We want to pour 150 g of VIWOOD resin in black color.

- We weigh 100 g of component A, add 4 g of VIVAT oxide black pigment, mix well

- add 50 g of component B (at room temperature we have about 20 min to work), mix well

- pour the mass into another cup, mix well again

- gently tap the cup on the surface to release air bubbles

- pour into the prepared mold or board, wait 24 hours for the mass to harden

- sand the surface, first with coarser sandpaper, then with fine water sandpaper

- polish the surface with polishing paste

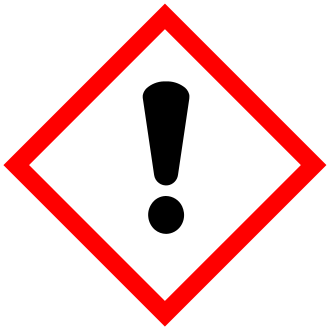

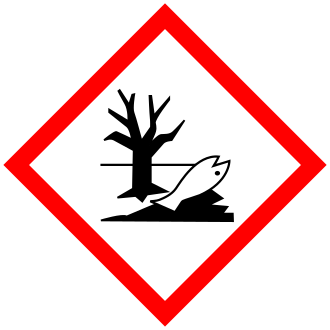

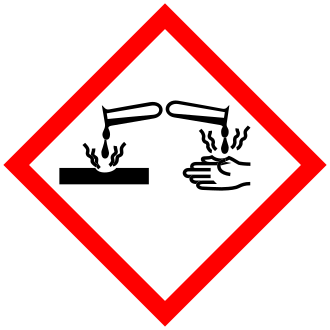

DANGEROUS

H315 Causes skin irritation.

H319 Causes serious eye irritation.

H317 May cause an allergic skin reaction.

H411 Hazardous to aquatic life with long-lasting effects.

H302 Harmful if swallowed.

H314 Causes severe skin burns and eye damage.

P102 Keep out of reach of children.

P305 + P351 + P338 IN CASE OF CONTACT WITH EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P310 Immediately call the POISON CENTER/doctor/….

P261 Do not inhale dust/fume/gas/mist/vapors/aerosols.

P273 Prevent release into the environment.